يُعتبر صندوق إغلاق المفاصل أمرًا بالغ الأهمية لتأمين المعدات بشكل كافٍ من الأضرار المحتملة بسبب الماء، الغبار أو أي عوامل بيئية أخرى. تكون الآلات والإلكترونيات المستخدمة في هذه القطاعات فعالة فقط إذا تم توفير بيئة آمنة ومقاومة للماء لها.

دليل شامل يناسب الجميع أثناء اختيار صناديق غلافات التقاطع يتضمن كل ما تريد معرفته حول: أنواع التغليف المائي، أفضل 5 علامات تجارية للاستخدام الصناعي والتركيب الذاتي + أشياء أخرى.

ويوفر هذا أيضًا بعض الفوائد الرئيسية من استخدام صندوق غلق المفاصل: الحماية المضادة للماء لأدواتك الثمينة، مما يعني أنها آمنة للاستخدام في الخارج في البيئة الرطبة؛ مثل المطر أو الثلج أو الرطوبة العالية. ومع ذلك، فإن إغلاق هذا الصندوق بشكل صحيح هو أمر حيوي لكي يعمل كمصدر مضاد للماء.

في البداية، من الضروري اختيار نوع正确的 من الختم. بين الأنواع المستخدمة لصناديق غلق المفاصل - وهي قائمة تشمل شريط البوليمر، والإيبوكسي وغيرها - يظل ختم السيليكون أحد أكثر الخيارات استمرارية.

الآن في عملية البحث عن المادة اللاصقة، اذهب وابحث في متاجرك المحلية. دع المادة تجف بمفردها بينما تعمل على تنظيف المنطقة حول صندوق الاتصال باستخدام ماء دافئ ومغسول خفيف. تأكد من أن المنطقة نظيفة تمامًا قبل الشروع في هذه العملية، ويُفضل استخدام فرشاة إذا بقيت أي أوساخ أو شوائب...

وأخيرًا، يجب تطبيق المادة اللاصقة في صندوق الاتصال بتغطية كاملة للأطراف، والخياطات، والثقوب. كل ما تحتاجه في هذه الخطوة هو مسدس لاصق للتطبيق السهل أو حتى فرشاة قديمة لتوزيع المادة على السطح بالكامل.

تأكد من أن المادة اللاصقة قد جفت تمامًا قبل الانتقال إلى الخطوة الثانية. قم بمراجعة العمل بشكل جيد وإذا لزم الأمر، أعطه طبقة أخرى من الماء الواقي.

استكشاف أفضل 5 علامات تجارية لصناديق الاتصال الصناعية

تم سؤاله عن أعلى 5 علامات تجارية لصناديق المعادن المقاومة للماء المستخدمة صناعيًا

هوفمان: هوفمان لديها تاريخ في الإبداع بالإضافة إلى قوة ضخمة تغلف بفترة خدمة متوقعة لا مثيل لها مخططة لجميع الحوادث البيئية، على عكس العديد من الأبعاد المستخدمة وأنواع التصنيف الخاصة بنظام NEMA.

ويغمان: اسم موثوق في صناعة الختم الرائد، ويغمان لديه العديد من الأنماط من الصناديق مثل الباب الواحد، الباب المزدوج والغطاء القابل للدوران.

ريتال: شركة ألمانية متخصصة في تصنيع صناديق الإغلاق المشتركة ونُظم التبريد حيث إن منتجاتها معروفة بجودتها الأفضل، الدعم لمدة أطول وكذلك المقاومة للبيئات القاسية.

أدا ليت: تقدم أدا ليت صناديق إغلاق مشتركة لمخاطر الانفجار تأتي في جميع الأحجام، مواد الفولاذ المقاوم للصدأ، مادة الألمنيوم أو الزجاج المقوى.

هاموند: معروف بسطحه المتين، تأتي صناديق الإغلاق المشتركة من هاموند بأبعاد مختلفة مصممة لتدوم عبر السنوات كذلك تحمل تصنيفات نمائية 4 و4X وأهم شيء تم مراجعتها.

إذا اشتريت صندوق غلاف المفاصل الخاص بك وترغب في معرفة مكان تثبيته، / كيف يحدث هذا - المقال التالي سيخبرك!

ما تحتاجه: حفار، مسامير ودعامات (إذا كنت تربط الصندوق بجدار ليس من الطوب الصلب) ومفك براغي.

تحديد منطقة التركيب: ضع الصندوق ثم أشر إلى المكان باستخدام مستوى.

الخطوة الرابعة - حفر بعض الثقوب: استخدم الحفار لحفر ثقوب مناسبة الحجم على الجدار وفقًا لمكان التركيب.

إدراج الدعامات - أضف الدعامات داخل الثقوب المحفرة وتأكد من وضعها بعمق كافٍ بحيث تكون مستوية أو قليلاً تحت هيكل الجدار.

تثبيت الصندوق: تأكد من أن فتحات التثبيت في الصندوق محاذاة مع الدعامات في الجدار وأحكم إحكام البراغي؛ وتأكد من وضعها بشكل صحيح.

الخطوة الثالثة: ربط المعدات بمجرد أن يكون لديك صندوق مؤمن في مكانه، هذه الصناديق مختلفة قليلاً، لذا اتبع تعليمات الشركة المصنعة حول كيفية ربط الأشياء بشكل صحيح.

من الأمور المهمة التي تحتاج إلى مراعاتها قبل شراء صندوق الإغلاق المشترك كاختيار مثالي تشمل.

المادة المستخدمة: المادة التي تم بناء هذا الصندوق منها لها تأثير مباشر على متانته وقوته، ومن بين المواد الشائعة التي تُستخدم عادة في صنع الصندوق الفولاذ المقاوم للصدأ، الألمنيوم أو الألياف الزجاجية على التوالي.

تقييم NEMA: هذا هو المعيار الذي يشير إلى مدى حماية الصندوق ويتم تمثيله بمعايير أكبر (أكثر مقاومة للأحوال الجوية) وأخرى أصغر.

في الوقت نفسه الحجم المتوافق: من أهم العوامل التي يجب مراعاتها عند شراء أي صندوق، تأكد من أن حجمه مناسب جيدًا للمكان الذي سيشغله.

الإحكام ضد الطقس: أخيرًا، مكان التركيب سيعتمد على نوع الطقس الذي قد يتعرض له مع مرور الوقت والصندوق الذي يجب عليك تركيبه.

الميزات الإضافية: تأتي بعض الصناديق مجهزة بميزات إضافية مثل منافذ التهوية، أنظمة التبريد ونظام القفل، لذا من الضروري التأكد من أن الصندوق يحتوي على كل هذه الميزات إذا كانت تطبيقاتك المقصودة تحتاج إلى واحدة منها.

على الرغم من أن صناديق الحماية تُصنع بشكل قوي وتُقصد بأن تكون دائمة، إلا أنها تحتوي على مكونات يمكن أن تتدهور إذا لم يتم صيانتها بشكل روتيني. المشاكل الشائعة والحلول المحتملة هنا بعض المشاكل الشائعة التي ستواجهها والحلول المحتملة لهذه الأخطاء أيضًا.

منع الصدأ - إذا اكتشفت وجود صدأ في الصندوق المعدني، فإن تطبيق طبقة من مانع الصدأ يمكن أن يساعد في منع التآكل الإضافي.

التحقق من ختم الصمغ لأي تلف وإجراء الصيانة الدورية سيحافظ على كفاءة العزل المائي.

تجنب التآكل: تجنب استخدام المواد التي تكون عرضة للتآكل، مثل الألمنيوم أو الزجاج المقوى في المناطق الرطبة.

تجنب الأخطاء الضارة بمنع تهوية الهواء المناسبة من خلال تركيب مروحة تهوية أو جهاز إزالة الرطوبة للمساعدة في التخلص من التكثيف الداخلي.

في النهاية، من الجميل دائمًا بالنسبة للأشخاص الذين يريدون أن يكون أداء معداتهم كامل الشكل وحمايتها من الكثير من الأوساخ حول الحقل بسبب جميع التغيرات البيئية كما قرأت. لذلك، يمكن أن تساعد الاحتياطات المناسبة وممارسات الصيانة، بما في ذلك جعلها مقاومة للماء، في زيادة عمر معدات الرياضة الخاصة بك. تذكر مراعاة العوامل الرئيسية عند اختيار صندوق إغلاق المفاصل، والتعرف على القضايا العامة المتعلقة بالصيانة لأنها ستبدأ في الظهور مع مرور الوقت.

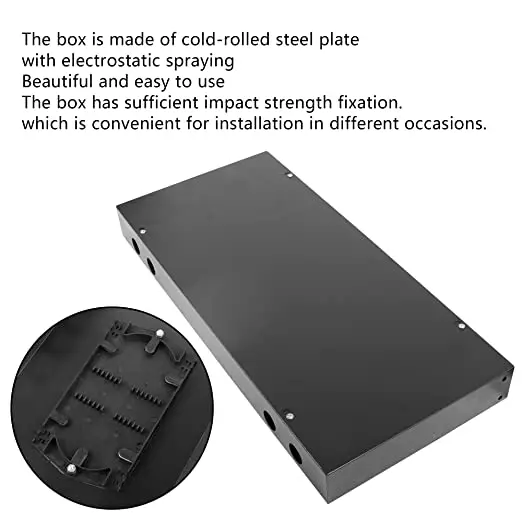

تُصنع القنوات الخاصة بمعدات الاتصال لدينا من مواد ذات جودة عالية وبمستوى فني استثنائي. يتم إنتاج هذه القنوات من صندوق غلق المفاصل باستخدام حرفة رائعة. نقدم لك مجموعة واسعة من المنتجات التي تأتي بمواصفات مختلفة لتلبية احتياجاتك المخصصة.

نقدم خدمات ما قبل البيع وما خلال البيع وصندوق الإغلاق المشترك. فريقنا الفني المهني يوفر للعملاء تقييمًا تقنيًا بالإضافة إلى تصميم الحلول وإرشادات التركيب. علاوة على ذلك، خدمتنا الصوتية بعد البيع تضمن وقت استجابة سريع وحلول فورية لاحتياجاتكم.

نحن متخصصون في الابتكارات العلمية والتقنية. نحن نعزز باستمرار استثمارات البحث والتطوير ونطور شراكات مميزة مع العلماء والمؤسسات البحثية والجامعات. نحن نواصل تطوير تقنيات جديدة ومنتجات ابتكارية لتلبية احتياجات صندوق الإغلاق المشترك المتزايدة.

مع أكثر من 20 عامًا من الخبرة في تصنيع الأنابيب لمعدات الاتصالات، قدمنا المعرفة الفنية العميقة وصندوق الإغلاق المشترك. مصنعنا الذي يبلغ مساحته 5,000 متر مربع مجهز بأحدث معدات الإنتاج بنظام فحص شامل. نلتزم بصرامة بالمعايير الدولية لضمان جودة المنتج المستقرة والموثوقة.

حقوق النشر © شركة قيتيان للاتصالات هاينان المحدودة. جميع الحقوق محفوظة - سياسة الخصوصية