In other words, Microducts is your answer to blazing fast internet and communication technology.

Nowadays, fiber optic networks have become the backbone of a huge portion among all data transfer communication and internet services that we use every day. However, laying fiber optic cables is difficult because cities are dense, and infrastructure already exists here.

For the fiber optics, well microduct technology has been making all things going smooth & being part of such a network performance lifeline ensure to keep everything (Latency issues + capacity) working on an expectation and for longer period. One solution is to use small, lightweight, high-flexibility conduits called microducts that can be installed in the narrow substructure of sidewalks or roadways or pulled through existing ducting systems. Deploying a much greater number of fiber optic cables, over shorter periods with less resources will provide network providers with an economy of scale in terms of both speed and cost.

Traditional fibre optic deployment has a lot of digging and trenching for the cable installations, adding on to traffic inconvenience, environmental damage along with time-consuming processes. Microduct technology, on the other hand is a trenchless alternative to traditional cabling methods that reduces or eliminates excavation and cable trench sizes which also decreases environmental impact while making the deployment process easier.

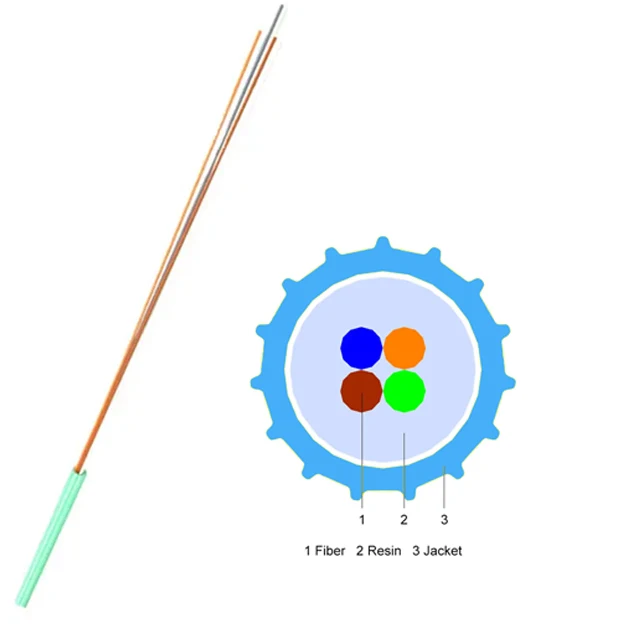

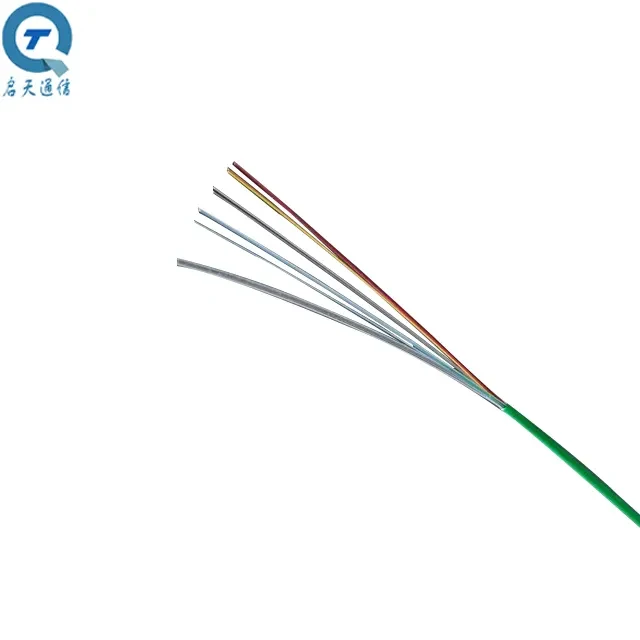

Microducts are created from a robust, flexible form of high-density polyethylene (HDPE), making them an ideal fit for all weather conditions and possible impact. The fiber count is higher to put more fibers per INSTALL SingleDuct, which also helps keep costs down and makes it easier for your systems.

Rather than pre-installed duct, Microduct technology also permits straightforward swapping or upgrading of fibres without the requirement to breakdown live networks. Microducts are easily be installed in existing ductworks or built into walls, pulled inside mircro- trenches / micro-drains Wheeled optical fiber cabeling system to make the fibre optic workable avaible at low cost also with faster and easier.

In urban environments, like downtown San Luis Obispo or in the northern Santa Barbara County communities where there isn't much room for new infrastructure in densely developed areas and running traditional fiber optic cable nearly private underground utility lines (or other contracting objects that require clearance from multiple agencies) adds a second level of complexity. And because microducts are smaller than conventional conduits, it allows for installations in an urban environment that demands minimal excavation.

Microducts micro fiber counts and can utilize slots in order text-multi-fibers-in-one duct for high cable deploying density of up to power next to other utility crossings. Microducts solve all the traditional challenges of fiber deployment in urban areas (underground utilities, street congestion and high-rise buildings).

Aside from this, the provision of fiber optic networks also has great benefits to offers broadband service providers in their deployment as they now have access advanced services like high-definition video streaming and broadband internet which helps to increase quality life with urbanisation. Namely, the quick transport of data and communication channels is a fundamental requirement for vital infrastructures such as hospitals, schools or any other public facility by far not only in one smart city - microduct technology should be an essential part of your plans.

Fiber optic networks are a necessity as data traffic increases daily along with higher bandwidth demands characteristic of the present digital age... Microducts help network providers increase their fibers-per-square-foot count and use smaller conduit. The new ultra compact MicroDucts significantly increase deployment possibilities by offering many more fibers per foot in less space than they would take up with traditional, loose tube designs, as well as add-on capacity to existing fiber infrastructure.

The microducts could host hundreds of fibers, so service providers began deploying the next 200-300% in cable capacity more cost effectively (& time wise - OPEX and CAPEX) than traditional conduit systems ever dreamed. This methodical overbuild and commercial allocation of cable capacity (granularity) also lends itself to a more targeted, DLC approach through providerscan dedicate specific rooms or each unit within communities or building footprints for new revenue streams sectors such as Public Wi-Fi, IoT networks Intelligent patriots.

Microduct fiber optic solutions offer that durability and flexibility however what sets it apart is the level of security, easy maintenance associated with outdoor installation. They simple connector with pressure handling features at wide range of crush test, temperature extremes, UV exposure in all harsh environments and assure the higher life cycle to Fiber Optic cables.

The microducts available in this product line is moderately flexible, it could wind around tight bends and corners without losing its performance. Microduct can be directly installed in IDF/MDF/ER closets, aerially and narrow pull boxes without the need of other special equipment that decreasekeeps installation rework errors ratio to zero.

So in short, Microduct technology is a revolution across the world for deploying fiber optic networks providing multiple benefits ranging from sustainable life cycle and cost effective installation of Optic Fiber Cabling. Microduct: an installation requirement that reduces costs, maximizes deployment efficiency and capitalises on current infrastructure for operators aiming to provide high-speed connectivity globally.

With most than 20 years' experience in manufacturing communication equipment conduits, we have gained the deep microduct for fiber and rich production enjoy. Our 5,000 square-meter factory is equipped with cutting-edge production equipment and an audio inspection system. We strictly follow international standards to make sure dependable and stable product quality.

We offer in-sales, pre-sales and after-sales support. Our expert technical team is in a position to provide clients with microduct for fiber, solution design, and installation guidance. Our dependable after-sales system provides rapid reaction time and prompt solutions to your needs.

Our conduits for microduct for fiber are made of high-end raw items with exquisite workmanship. These conduits are made from high-end natural materials which are crafted utilizing exquisite workmanship. We offer the wide range of services and products which come with different specifications to meet your individual modification needs.

We are specialized in scientific and technical innovations. We constantly enhance R and D investments and develop an enviable partnership with scientists, research organizations and universities. We continuously build new technology and innovative products to meet the constantly microduct for fiber.

Copyright © Qitian Communication Industry Ningxia Co., Ltd All Rights Reserved - Privacy Policy