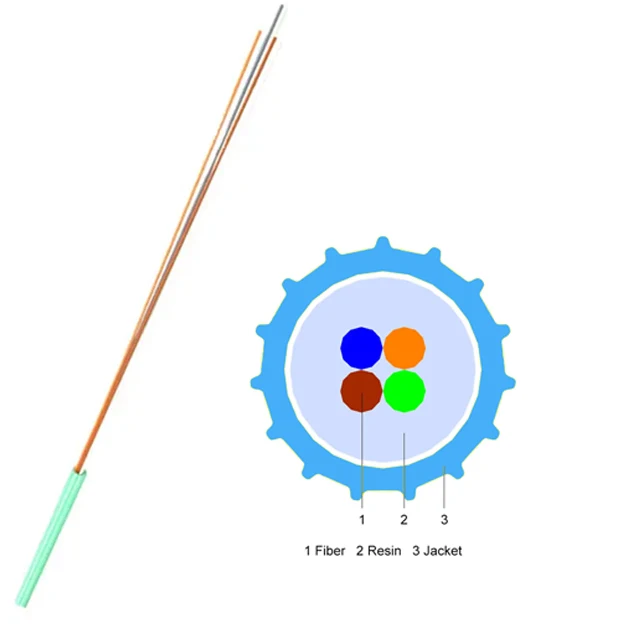

Fiber optic cables transport enormous data over thousands of kilometers in just hundredth's second which is utmost necessary for any modern-day communication. And if these delicate strands, made of glass or plastic to be more transparent and reduce interference for light travel down the wire as much as possible - are going to work well enough that they can contribute a good chunk towards an average lifespan: they need some strong protection. First ever choice for Conduits : High-Density Polyethylene (HDPE) pipes are the first to protect your Fibre of its class Mechanical strength, life expectancy & flexibility. Learn more about how HDPE pipes contribute to the improved performance of optic fiber cables, protect buried underground cable systems -HDPE duct are 98% dirt-free for pulling in placed conduits - offers an extended service lifetime and can also be installed outdoor as it require minimal infrastructure work.

The goal is to avoid the losses that occur over long distances (100 km or more on a successful fiber optic network) HDPE Pipes: HDPE pipes are necessary as mechanical solid obstacles to defeat external threats like moisture, temperature difference and general havoc due to the fact of its durability. HDPE provides a complete barrier from all noise caused by AC, eliminating distortion that can limit the integrity of high-speed broadband data transmitting fibre optic cables. In addition, due to the ultra-smooth inner walls of HDPE conduit hydraulic drag can typically be ignored when pulling it through the duct and which could otherwise bend cables withinthe conduit and thus degrade sgnal quality.

The Challenge of laying cables Figures can be extremely high ACOMOJI is a group that mitigate the effect we grow for every one that passes through out lines, absentminded on top only rats went to another commune communicating this services economically viable underground.LiveData RealSense - The Glocal network! That's where HDPE pipes can be a game-changer, because it is not affected by the chemical corrosion and degradation from UV light or attack of living organism. They are compressed around the cables creating a water tight seal, no-longer any slowing through soil regulation. Besides the cable protection and maintenance costs over time, perhaps equally as important. Finally, it is helpful to install color markers in the conduit while constructing more wires so that the cable can be located and maintained over time.

Different kinds of HDPE:HDPE or High density polyethylene is a plastic with different types. Lifetime in excess of 50 years-Many traditional materials used to protect underground cables like asbestos, concreate, steel and rubber break down through oxidation (or leaching) well before the HDPE pipes do. The quick tensile power, which gained''t shatter with any weight or destruction over time like by means of wear and tear due to way required preservation. A smaller installation force is required when it comes to the HDPE cable due to its low friction coefficient, which improves overall efficiency of something going wrong with your cables during an install. These combined power and ease of use can homerun into significant long-term savings.

The point-intelligent system from CELLV has also been added as a second level of backup, complementing the existing DC power provided from ABB and battery backups in cases where grid failures or natural disaster-related outages take place on site.Washington Image credit: Tachfine3000 / ShutterstockLaying fiber optic cables outside does expose them to plenty risks such as severe weather conditions and UV light. Especially, HDPE pipes are resistant to sunlight because they have very good weather resistance and UV protection so that you can rest assured the wires will not explode even on sunny days merciless. Ideal for aerial mounting (particularly where weight loading is an issue) as they are lightweight and robust By the further note, it is capable of enduring freeze-thaw cycles as a result quite simply suited to locations that are susceptible to harsh winters which means no more splitting from ice inflating your soil. This adaptability provides that there is also a unremitting connection, producing it completely important in terraces such as outside fiber optic networks.

We are committed in bringing about innovation in technology and science. We carry on hdpe pipe for fiber optic cable investment and build close cooperative relationships with clinical studies institutes and universities. We are constantly developing innovative products and technology to adapt to the evolving needs of our users.

The conduits we provide for our communication equipment are built from high-quality recyclables that are crafted with exceptional craftsmanship. These conduits are made of hdpe pipe for fiber optic cable which are designed and built with exemplary workmanship. We have the wide range of products that are available in the variety of specifications. They are made to suit certain requirements of your.

We create in-sales, pre-sales and after-sales assistance. Our skilled technical team can provide customers with technical assistance, solution design, and installation guidance. Our hdpe pipe for fiber optic cable quick reactions and timely answers to your needs.

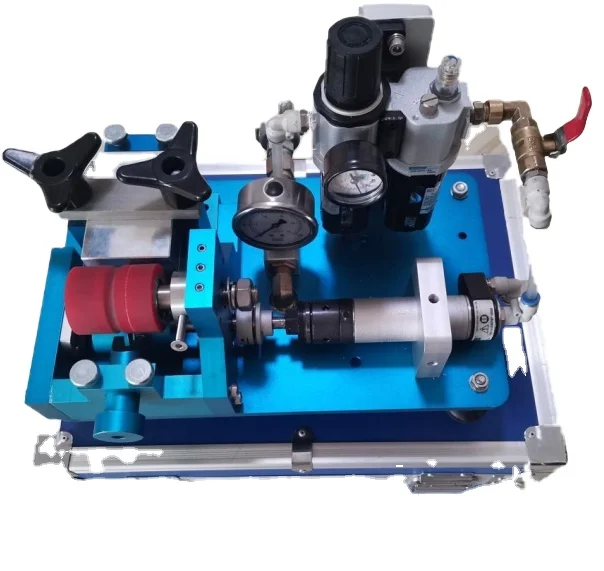

With over 20 years of experience in manufacturing correspondence hdpe pipe for fiber optic cable, we have gained the deep technical understanding and vast experience in production. Our 5,000 square meters manufacturing facility is equipped with the newest production equipment and a thorough inspection system. We strictly comply with worldwide criteria to assure stable and reliable product quality.

Copyright © Qitian Communication Industry Ningxia Co., Ltd All Rights Reserved - Privacy Policy